Phone: 01295 714056

A range of tools specifically created for the manufacturing process to give you accurate, instant, reliable and error-free information to maximise your control.

Define exactly what and how many parts, components or materials are required to complete a production run.

Basically, it’s a manufacturing recipe and instructions about what to use, how long it will take, and how much it will cost in order to produce your product and is a critical component in the manufacturing process. Optionally it has an interdependent relationship with the MRP and Forecasting modules.

Drive improved production management using industry-standard techniques.

Balance customer demand, accurately forecast requirements, plan production with pin-point accuracy, and make last minute changes to a scheduled production run.

Eliminate the costs associated with dissatisfied customers with automated quality control processes.

Have you ever had to return an item to the manufacturer or retail outlet because it was faulty, damaged or outright broken? Irritating isn't it? Most of us have had to do this at least once in our lives and the nuisance value of the whole process can't be understated. Testing for quality assurance is an afterthought for some businesses or not part of the manufacturing process at all for others where the urgency to get products out the door takes precedence. The outcome becomes an exercise in false economics as the cost of having dissatisfied customers is considerable and over time will surely exceed the investment required for a robust Quality Control process.

Schedule and manage the testing of assets, pre-define standards to ensure that faulty goods are never released and track products right through to customer by serial number.

Easily and accurately manage the assembly of products for make to order and make to stock manufacturing requirements.

The ability to respond quickly to customer requirements is key in today’s market. Greentree Factory Orders is a key component in our Manufacturing suite which ensures you know exactly what materials are required, at what cost, providing responsive customer delivery at appropriate pricing and profit margins.

Make forecasting an easy-to-manage process; once the criteria is established the forecast is automatically generated for you.

The Forecasting module uses historical sales data, mathematical calculations and human intuition to forecast future inventory requirements. It allows for seasonal fluctuations and ensures that forecasting matches the natural curve of your business demand.

You can make manual adjustments for unusual events or unexpected demand so you're always on-track.

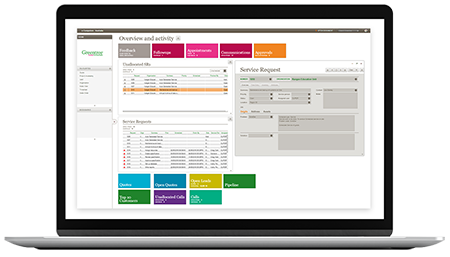

Greentree ERP Software is designed to make businesses more effective and more profitable. It's a completely integrated, unified solution. Simply turn on what you need knowing that the modules work cohesively because they're all on one complete business management platform which is fully HMRC compliant for UK Payroll.